- Phone : (+91) 9842727266

- Email us: [email protected]

- Whatsapp : (+91) 9842727266

Quality Specification

- Home /

- Quality Specification

Design Considerations

We would suggest that before any project is designed for a new building that the following practical information's is considered at the earliest stage.

• Public Safety

• Structural Requirements

• Wind load

• Weather Resistance

• Maintenance

• Colour Finishes.

Public Safety

We are an excellent record of public safety. The following details can serve as a guide for selection of a suitable safety glass in any our overhead glazing systems.

Glazing Height Above The Floor Level: 0-5 meters - The glass should be toughened or laminated.

Structural Requirements

We are designed our own die for using the Aluminium Sections to resist the most adverse combination of loads likely to occur, such as dead load (self weight), wind,

snow and where necessary, maintenance consideration. Therefore consultation with us at design stage is recommended for most contracts.

Weather Resistance

Experience has shown that our glazing system used in sufficient pitches will be provided for excellent weather resistance.

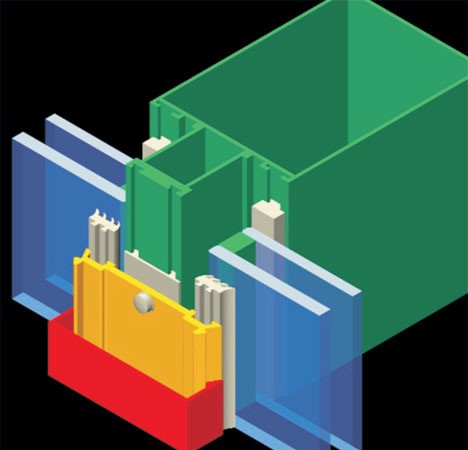

ALUMINIUM EXTRUSION

Aluminium Extrusion used in Structural Glazing, Stick Glazing, all type of Windows, Doors. Aluminium Extrusion shall be 6060-T6 alloy conforming to BS-1474-1987. The extrusion shall be Clean. Straight with sharply defined lined and free from distortion and defects impairing appearance, strength and durability. The extrusion shall be suitable for wall thickness and profile for rigidity and strength in respect to tensile, shear, bending and bearing stresses, capable of providing local and lateral stability.

ANCHORAGE SYSTEM

The structural glazing system, will be fixed to the main building structure using components of alloy steel or other materials appropriate and conforming to statutory requirements and coded of practices. In general, Galvanized steel bracket shall be used as the anchoring system. The type size of the bracket is to be selected in accordance with engineering calculations to withstand 200 Kg/Sqm x 1.5 times for safety factor. Mullions shall be mounted to the brackets of desired thickness and size. All fastening and transoms shall be of stainless steel bolts and nuts with spring washers.

GLASS FOR STRUCTURAL GLAZING, WINDOWS & FIXED GLAZING

The glass will be approved make and will be in a position to take the required wind load specified by the architect. The glass samples will be submitted for approval.

SILICON SEALANT

Sealant for weather seals shall be Dow Corning 789 or Equivalent. Sealant for Structural Glazing shall be Dow Corning 995 or Equivalent and shall be applied in accordance with manufacturer’s specification.

HARDWARE FITTINGS

All screws, plugs, nuts or other fastening devices shall be of stainless steel that will not result in the corrosion with installation. 4 bar stays stainless steel arm shall be used in openable windows of along with peg stays for openable window.

WEATHER STRIPPING

Weather Stripping shall be extruded Neoprene / EPDM or Equivalent and of the required size.

GLAZING TAPE

Glazing Tape for Structural Glazing will be special two ways adhesive Black coloured Tape equivalent to Norton Tape.

QUALITY CONTROL DOCUMENTATION

- Quality Control procedures shall be documented in writing for the Engineer’s review and approval to ensure the design integrity and performance of the as-built product.

- Documentation shall include schedules, details and explanatory sketches cross-referenced to the shop drawings etc., all as required to intelligently witness and assess methods and materials; and to ensure that both the fabrication and installation are in accord with the contract documents.

- The Engineer shall, if required, be given free access to the site to inspect fabrication procedures. The quality control procedures shall include but not be limited to the following items;

- Materials – Visual inspection, field tests.

- Fabrication – Tolerances, Joinery, Sleeves

- Finish Match – Approved finish and controls required for matching the exposed surfaces.

- Assembly – Welds, fasteners, sealants, gaskets, glazing, bite.

- Protection – Handling, Protection, was shipping.

- Anchorage – Lines, grades and related building tolerances.

- Installation – Setting-out, tolerances, finish match, connections, sleeves, flashing, welds, Fasteners, sealants, bolt tension.

- Sealing – As recommended by the sealant manufacture(s).

- Storage – As recommended by the manufacturers.

- Protection & cleaning – As recommended by the material manufacturers.

FABRICATION MACHINERY'S:

The Company has well equipped with imported machinery like End Milling Machines, Router Machine, Corner Cutting Crimping Machines, Cutting Machine, Pneumatic End Milling Machine etc.,

- Dewalt Portable Cutting Machine – 17 Nos

- Bosch Portable Drilling Machine – 24 Nos

- Dewalt Portable Hammer Drill – 18 Nos

- ACP Revolting Machine – 11 Nos

- Glass Holder(Griper) – 24 Sets

- Safety Accessories – 40 Sets